how to perform vickers hardness test|vickers microhardness test procedure : member club How Does a Vickers Hardness Tester Work? 1. Preparation. 2. Application of Load. 3. Indentation. 4. Measurement. 5. Calculation. 6. Determination of Hardness. 7. Reporting. Advantages of Vickers Hardness Tester. 1. Broad . Vendido por Lojas Koerich. R$ 2.199,00 R$ 1.790,00 à vista. .

{plog:ftitle_list}

WEB20 de fev. de 2024 · Read Chapter 30 of Craft Game No Nouryoku De Isekai Kouryaku!! without hassle. Read When I Was Reincarnated in Another World, I Was a Heroine and He Was a Hero Chapter 7: If Youre A Hero - Keito Azumi, an ordinary high school boy, was reincarnated as the heroine in a different world when he woke up in an accident! The .

vickers microhardness test procedure

moisture analysis meter group

vickers hardness test procedure

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .How Does a Vickers Hardness Tester Work? 1. Preparation. 2. Application of Load. 3. Indentation. 4. Measurement. 5. Calculation. 6. Determination of Hardness. 7. Reporting. Advantages of Vickers Hardness Tester. 1. Broad . What is the Vickers Hardness Test. NextGen explains the machine, its applications and the necessary consumables required for the Vickers Hardness Testing needs.

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of h.The Vickers hardness test is suitable for a wide range of applications, including micro hardness testing. On this page, you can find a description of the Vickers hardness test, practical information on how to apply it and a list of our micro .A Vickers hardness testing machine was employed to determine the hardness differences of all the rolled strip specimens in the thicker, thinner, and transition zones by applying a load of 1 N .

Basic principle and practical procedure of the Vickers hardness test - Testing machine, test piece, diamond pyramid indenter - Basic principle, hardness de.The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the .

moisture and ph meter for worm

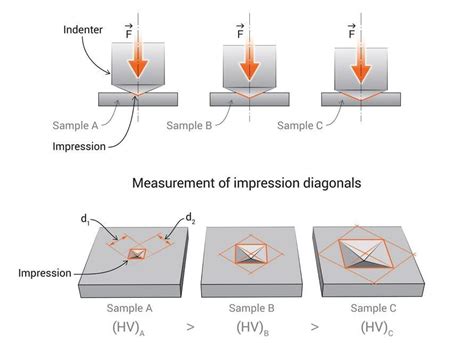

During the Vickers Hardness test, a pyramid-shaped diamond indenter is used to create a permanent indentation in the material under test by applying a specific load. This .Vickers hardness testing is extensively used in the metals and alloys industry to evaluate different metallic materials' hardness, strength, and durability. This instrument helps evaluate metallic components' hardness, strength, and .Hardness tests measure the resistance of a material against plastic deformation.To perform these tests (be it Brinell, Rockwell, or Vickers), an indenter is pressed on the surface of the specimen with a specific force F F F .When needing to perform hardness testing on-site or non-destructively – the Leeb hardness test provides portability and convenience. . The Vickers hardness test utilises a diamond pyramid-shaped indenter to create a small .

The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface.15.2.3.2 Hardness Test. A Vickers hardness testing machine was employed to determine the hardness differences of all the rolled strip specimens in the thicker, thinner, and transition zones by applying a load of 1 N with a dwelling time of 12 s. Hardness measurements were performed on the cross-section surfaces of the rolled strips along the . A Vickers hardness testing machine can share the same components and layouts as Brinelle and Rockwell testers. However, what makes it unique is the use of a universal indenter which allows for ease of maintenance. Also, the Vickers tester measures hardness by the Vickers Hardness Value (symbolized as HV) or the Diamond Pyramid Hardness Value .

The Vickers hardness test is a very reliable method for measuring the physical properties of materials. It is a very popular method in engineering, industrial use, and the oil and gas industries. The article is all about the principle and application of Vickers hardness test. + 86 755 61301520; [email protected]; Search.

3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.

640 is the numeric value representing the Vickers hardness of the material. HV is the abbreviation representing Vickers hardness. 30 represents the load applied to the indenter. (a force of 294.2 N ) Example 2: 610 HV10/30. 610 is the numeric value representing the Vickers hardness of the material. HV is the abbreviation showing the Vickers .

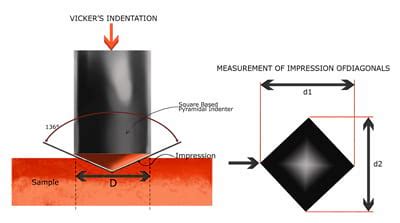

The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds. The two diagonals of the indentation left in the .

The Vickers hardness test measures material hardness by determining the size of an indentation made by a diamond pyramid-shaped indenter under a specific load. A load ranging from 1 gf to 100 kgf is applied to the material’s surface, creating a square-shaped indentation. After the load is removed, the diagonals of the indentation are measured . Basic principle and practical procedure of the Vickers hardness test - Testing machine, test piece, diamond pyramid indenter - Basic principle, hardness de. Brinell Hardness Test. The Brinell hardness test entails measuring the diameter of indentation caused by a constant concentrated force applied by a steel or carbide spherical indenter on a test specimen. The steel ball indenter is first placed in contact with the material before a constant force is applied and maintained for a 10 to 15 second duration, known as the .Vickers Hardness Testing Formulas, Calculator and Review . The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number ( HV ) or Diamond Pyramid Hardness ( DPH ). The hardness number can be converted into units of pascals , but .

For the Vickers hardness test, a square base pyramid with a opening angle of 136° is used as the indenter (opening angle = angle between two opposite surfaces of the pyramid). The angle was chosen so that the .

The Vickers method has the following advantages: The Vickers method can be used with any and all materials and test specimens, from soft to hard, as the procedure covers the entire hardness range.Vickers Hardness Test. The Vickers hardness test operates on similar principles to the Brinell test, the major difference being the use of a square based pyramidal diamond indentor rather than a hardened steel ball. Also, unlike the . The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. Characteristics and Application of Vickers Hardness (1) The geometrical shape of the indentation is always similar, while the load can be varied.

Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. The Rockwell test is generally easier to perform, and more accurate .II. Principle of Leeb Hardness Test. The principle of the Leeb Test depends on a combination of friction, elastic and plastic deformation. When a material is subjected to a tensile force, the deformation element (i.e., the carbide ball) glides against the material’s surface.

In Vickers hardness testing, a square pyramidal diamond indenter with specified face angles is used (see figure below). After the pyramidal diamond tip (indenter) is pressed into the test sample at a perdetermined load (F[N]), the indentation on the sample is measured using a microscope.

The Vickers hardness test is a static hardness test method, used for both macro and microhardness testing. It is an optical method of testing where the size of the indentation left by the indenter is measured to determine the hardness value of .

The Brinell hardness test is a standardized test used for measuring the hardness of metals and other hard materials. Do not know how to perform a Brinell Hardness test? This is an article to teach you detailed Brinell Hardness tests procedure on various materials.

The Vickers hardness test can be a micro indentation test and also for the macro hardness test. It is mainly divided into two steps. The test force (load) F is applied on the specified square base pyramid shaped diamond indenter for the specific time when it collides with the testing sample object in the direction normal to the test surface. To perform a Vickers Hardness test, light loads are applied to small, thin samples that require a smooth or polished surface before testing. During the test, a pyramid-shaped diamond indenter is placed on a section of the material, and a constant load (ranging from 0.3kg to 10kg) is applied for a specified time according to international .To perform the Vickers hardness test, a pyramid-shaped diamond indenter with a load ranging from 1gf to 120kgf is often applied to the surface of a test material. Leaving the load after application for 10 to 15 seconds allows the indenter to stabilize before removing the load. The width of the impression made on the material surface is measured .

Rockwell hardness testing, Brinell hardness testing, and microhardness testing are all methods used to verify heat treatment results. . It’s also critical to specify the correct load for Knoop tests because too-light loads could produce falsely high hardness readings. For Vickers tests, too-light loads create too-small indentations on a .

web12/09/2023 Governo Do Tocantins Lança Iniciativa Para Combater o Desmatamento Ilegal No Dia Do Cerrado; 16/09/2023 Indígena é Morto Com Requintes de Crueldade no Centro de Tocantinópolis; 27/06/2023 Tocantinópolis: Acidente Com Pá Carregadeira Mata Empresário do Ramo de Materiais Base Para Construção

how to perform vickers hardness test|vickers microhardness test procedure